Application of sodium chlorite in leather manufacturing

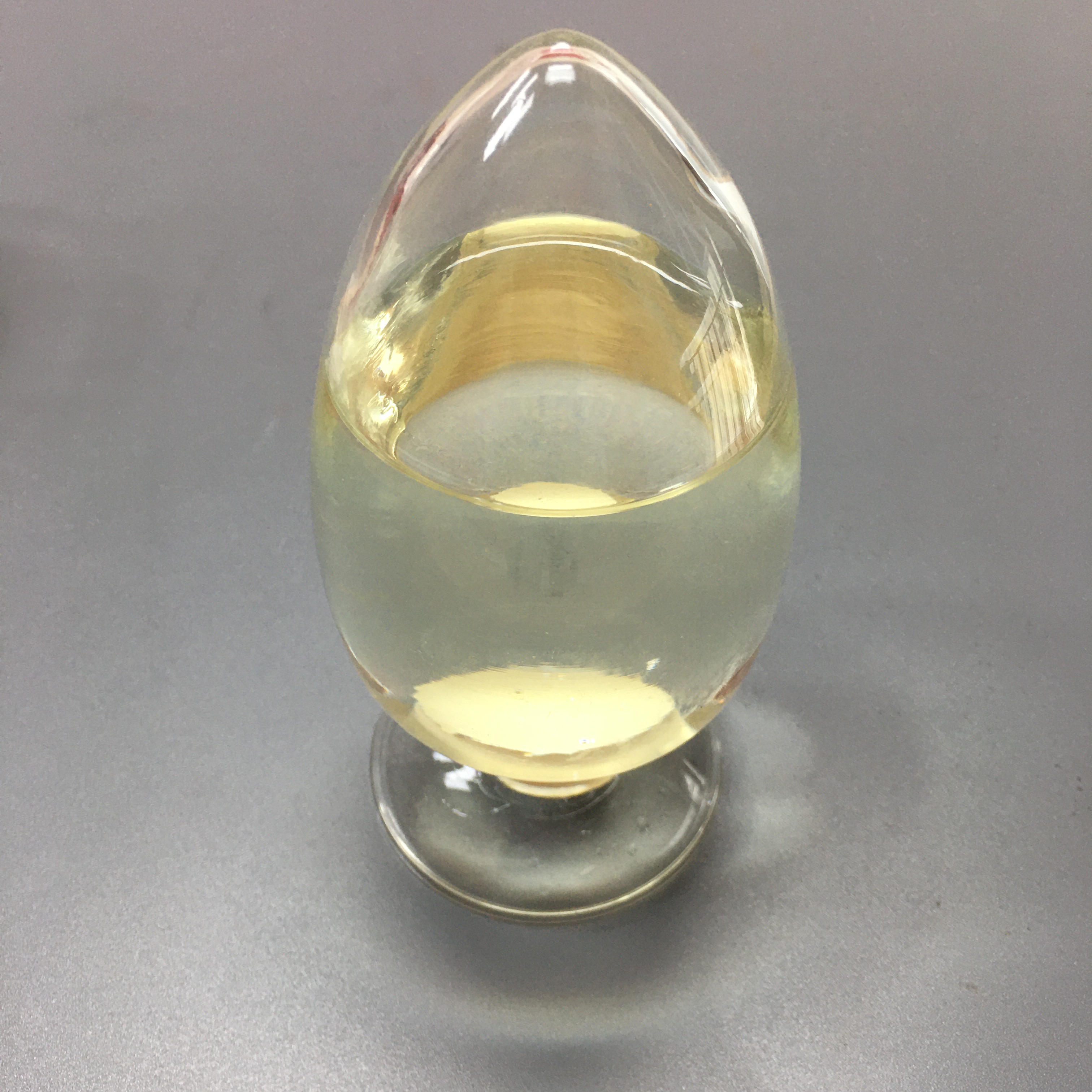

Sodium chlorite (NaClO₂) is mainly used as a bleaching agent and oxidant in leather manufacturing. Its role is specifically reflected in the following aspects:

1. Bleaching effect

Removing pigments: Sodium chlorite can effectively oxidize and decompose natural pigments in leather (such as heme, tannin pigments, etc.), making the leather lighter or more uniform in color, especially suitable for producing light-colored or white leather.

Improving appearance: Bleaching can reduce the color spots or uneven dyeing on the leather surface and improve the appearance of the finished product.

2. Oxidative decomposition of organic impurities

Degreasing assistance: After the dehairing and degreasing processes, residual fat, protein and other organic matter may affect the tanning effect. The strong oxidizing property of sodium chlorite can decompose these residual impurities and improve the cleanliness of the leather.

Degrading lignin: If the leather raw material (such as tree paste skin) contains plant fiber impurities, sodium chlorite can help degrade lignin and make the fiber structure looser.

3. Sterilization and preservation

Inhibit microorganisms: In the wet processing stage (such as soaking and tanning), sodium chlorite can inhibit the growth of bacteria and mold, prevent leather from rotting due to microbial action, and extend the shelf life of raw materials.

4. Assisted depilation

Destroy hair follicles: Under alkaline conditions, sodium chlorite can oxidize keratin in hair, weaken the connection between hair and cortex, and assist the traditional lime-sodium sulfide depilation process, but the concentration needs to be controlled to avoid excessive damage to collagen fibers.

5. Improve the effect of subsequent treatments

Enhance tanning uniformity: Leather fibers after bleaching and cleaning are easier to combine with tanning agents (such as chromium salts, vegetable tanning agents), improving tanning efficiency.

Optimize dyeing/finishing: Crust leather with uniform color is easier to color, reducing subsequent uneven dyeing or coating covering problems.

Notes

Concentration control: Excessive use may cause fiber strength to decrease and make leather brittle.

Environmental protection and safety: Sodium chlorite may produce harmful gases such as chlorine dioxide (ClO₂) when it decomposes. It needs to be operated in a ventilated environment, and wastewater needs to be treated to meet environmental standards.

Alternatives: Due to environmental and health risks, some factories have switched to more environmentally friendly oxidants such as hydrogen peroxide and ozone.

Tianjin Sino Chemical Co., Ltd. cooperates with many famous leather manufacturers in the world. These products are supplied to top international brands and have been well received by customers. All friends who have demand for sodium chlorite are welcome to contact Sino Chemical for inquiries.

Contact: Monica

whatsapp:

Monica

Monica

Phone: +8613342014397

Tel: 022-25220868

Email: info@tjchemi.com

Add: Tianjin, China